Ha o rekaPolyaluminum chloride(PAC), e leng coagulant e sebelisoang haholo lits'ebetsong tsa kalafo ea metsi, matšoao a 'maloa a bohlokoa a lokela ho hlahlojoa ho netefatsa hore sehlahisoa se fihlela maemo a hlokahalang 'me se loketse ts'ebeliso ea sona e reriloeng. Ka tlase ke matšoao a mantlha ao u lokelang ho tsepamisa maikutlo ho ona:

1. Dikahare tsa Aluminium

Karolo e ka sehloohong e sebetsang ho PAC ke aluminium. Katleho ea PAC e le coagulant e itšetlehile haholo ka bongata ba aluminium. Ka tloaelo, bongata ba aluminium ho PAC bo hlahisoa e le peresente ea Al2O3. PAC ea boleng bo holimo ka kakaretso e na le pakeng tsa 28% le 30% ea Al2O3. Bongata ba aluminium bo lokela ho lekana ho netefatsa ho kopana ho sebetsang ntle le tšebeliso e feteletseng, e leng se ka lebisang ho se sebetseng hantle ha moruo le litlamorao tse mpe tse ka bang teng boleng ba metsi.

2. Motheo

Basicity ke tekanyo ea tekanyo ea hydrolysis ea mofuta oa aluminium ho PAC 'me e hlahisoa e le peresente. E bontša karolelano ea li-ion tsa hydroxide ho aluminium ka har'a tharollo. PAC e nang le sebaka sa basicity sa 40% ho isa ho 90% hangata e khethoa bakeng sa lits'ebetso tsa kalafo ea metsi. Basicity e phahameng hangata e bolela ho hoama ho sebetsang hantle empa e tlameha ho leka-lekana khahlanong le litlhoko tse ikhethileng tsa ts'ebetso ea kalafo ea metsi ho qoba ho phekoloa ho feteletseng kapa ho se phekoloe hantle.

4. Maemo a ho se hloeke

Boteng ba litšila tse kang litšepe tse boima (mohlala, loto, cadmium) bo lokela ho ba bo fokolang. Litšila tsena li ka baka likotsi bophelong 'me tsa ama ts'ebetso ea PAC. PAC e hloekileng haholo e tla ba le maemo a tlase haholo a litšila tse joalo. Maqephe a litlhaloso a fanoeng ke bahlahisi a lokela ho kenyelletsa tlhahisoleseling mabapi le mahloriso a phahameng a lumelletsoeng a litšila tsena.

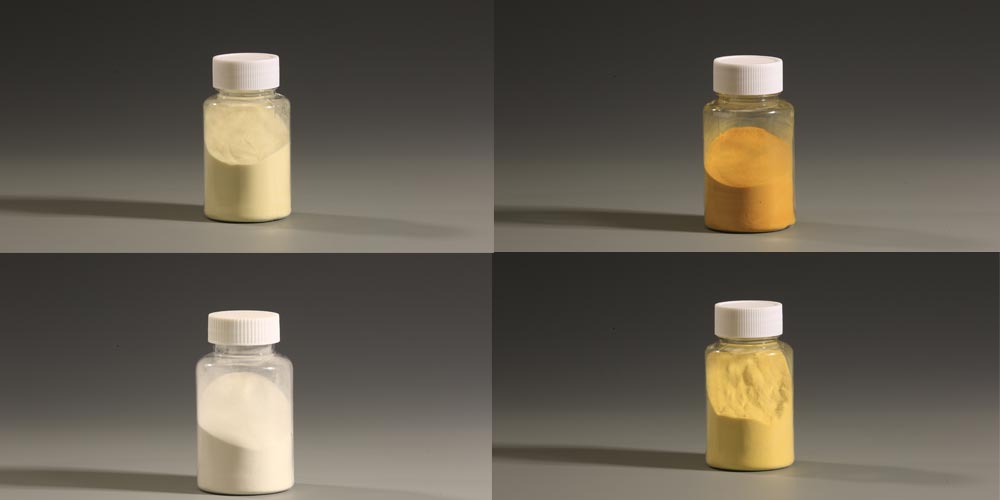

6. Sebopeho (Se tiileng kapa se Metsi)

PACe fumaneha ka mefuta e tiileng (phofo kapa di-granule) le ya mokelikeli. Kgetho pakeng tsa mefuta e tiileng le ya mokelikeli e itshetlehile hodima ditlhoko tse ikgethang tsa semela sa kalafo, ho kenyeletswa le dibaka tsa polokelo, disebediswa tsa tekanyo, le bonolo ba ho sebetsana. PAC ya metsi hangata e kgethwa ka lebaka la bonolo ba yona ba ho e sebedisa le ho qhibiliha kapele, athe PAC e tiileng e ka kgethwa bakeng sa melemo ya polokelo ya nako e telele le ya dipalangwang. Leha ho le jwalo, nako ya ho boloka metsi e kgutshwane, kahoo ha ho kgothaletswe ho reka metsi ka kotloloho bakeng sa polokelo. Ho kgothaletswa ho reka metsi a tiileng mme o iketsetse ona ho ya ka karolelano.

7. Bophelo ba Shelefo le Botsitso

Ho tsitsa ha PAC ha nako e ntse e ea ho ama ts'ebetso ea eona. PAC ea boleng bo holimo e lokela ho ba le nako e tsitsitseng ea ho boloka lintho, e boloke thepa ea eona le katleho ea eona ka nako e telele. Maemo a polokelo, joalo ka mocheso le ho pepesehela moea, a ka ama botsitso, kahoo PAC e lokela ho bolokoa sebakeng se pholileng, se omileng ka har'a lijana tse koetsoeng ho boloka boleng ba eona.

8. Ho Sebetsa ka Botlalo Litšenyehelo

Ntle le boleng ba sehlahisoa, ho boetse hoa hlokahala ho nahana ka katleho ea theko ea thepa. Bapisa litheko, liphutheloana, lipalangoang le lintlha tse ling tsa bafepedi ba fapaneng ho fumana lihlahisoa tse nang le katleho e loketseng ea litšenyehelo.

Ka bokhutšoanyane, ha o reka polyaluminum chloride, ho bohlokoa ho nahana ka litaba tsa aluminium, motheo, boleng ba pH, maemo a litšila, ho qhibiliha ha eona, sebopeho, nako ea ho boloka litšenyehelo, katleho ea litšenyehelo, le ho latela melao. Matšoao ana ka kakaretso a khetholla ho tšoaneleha le katleho ea PAC bakeng sa lits'ebetso tse fapaneng tsa kalafo ea metsi.

Nako ea poso: Mots'eanong-31-2024